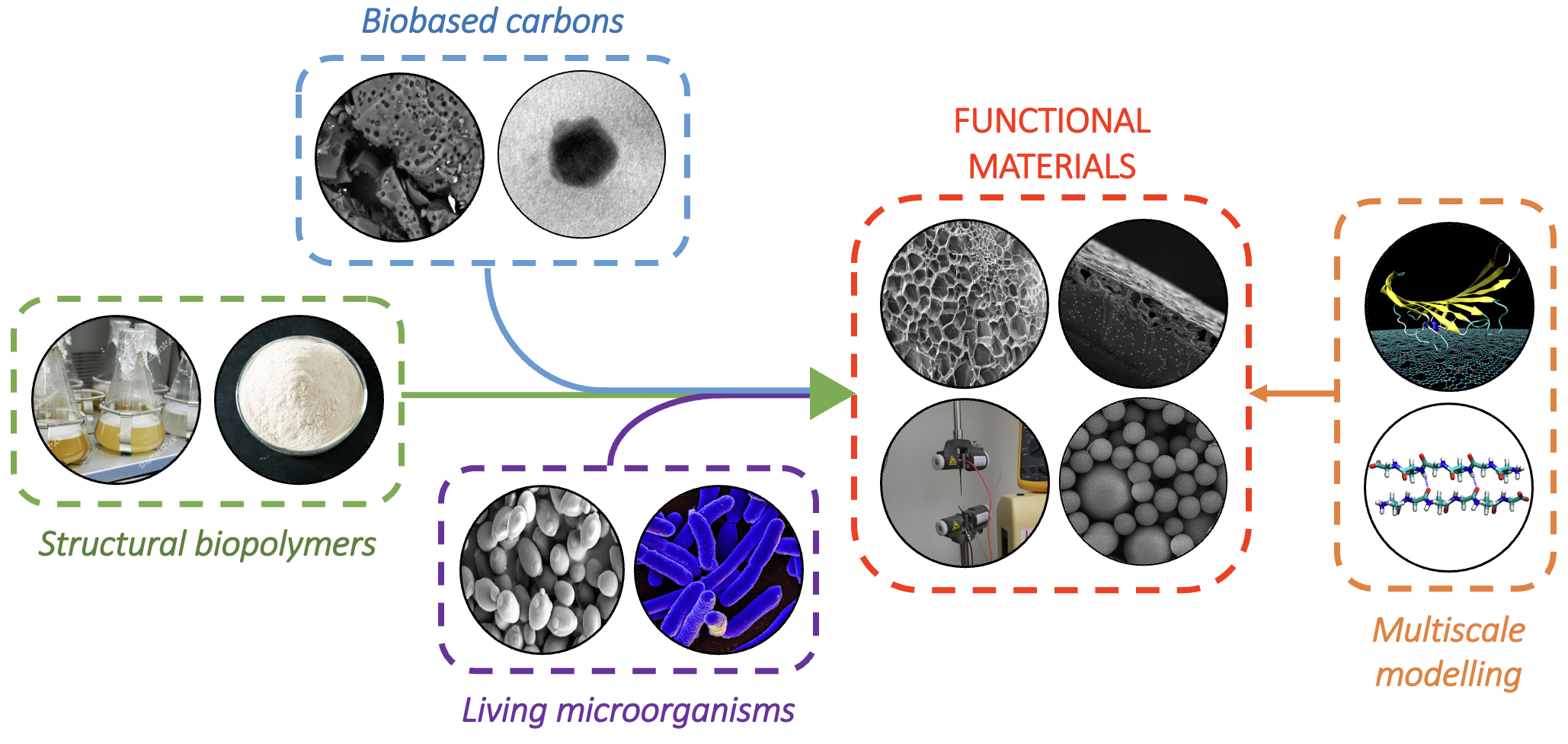

Our group is part of the Department of Chemical Engineering, the Manufacturing Futures Lab (MFL), and the Centre for Nature-Inspired Engineering (CNIE). We use biopolymers to develop functional materials, alone or in combination with additives like (i) microorganisms that synthesise functional molecules to create living materials; or (ii) biobased carbons or biominerals to create composite materials. The aim is to invent new materials with tailored nanostructures, controlled interfacial chemistry, and advanced physicochemical or biological functionalities that can interact with the environment, other biomolecules, or living tissues. Our experimental work is supported by multiscale computation to connect molecular-based nanoscience with the macroscopic behaviour of our materials.

Read more about our research topics:

- Structure-property relationships for biopolymeric materials

- Living and composite biopolymeric materials

- Structure-property relationships for biopolymeric functional materials

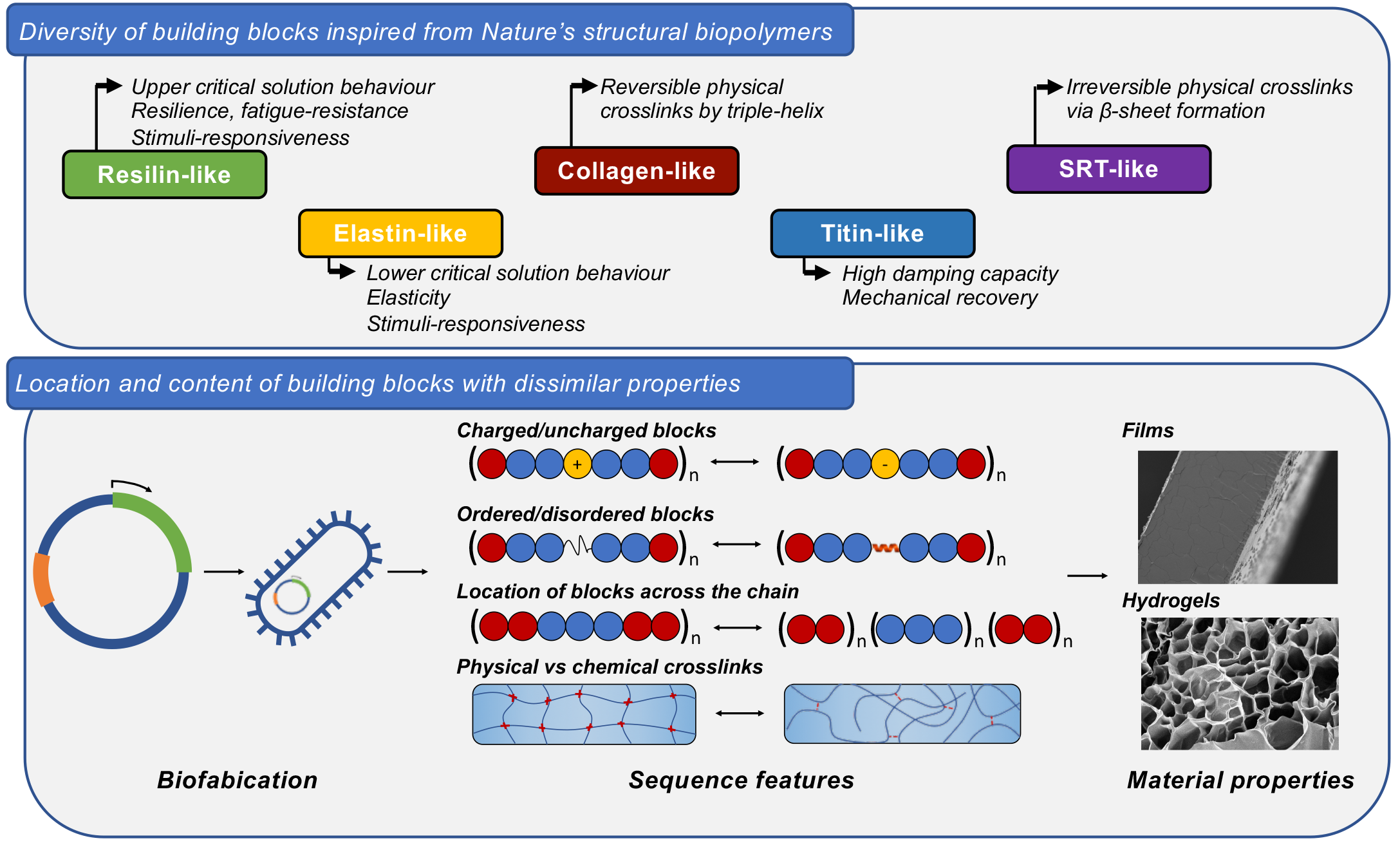

Structural biopolymers

Biopolymers have a propensity towards molecular self-assembly and self-organisation that underpins their ability in living organisms to generate natural functional materials with remarkable performance. Thus, these biopolymers are gaining increasing attention as alternative building blocks to replace fossil-based polymers as source of synthetic functional materials. Developments in molecular biology are making it increasingly possible to design e.g., novel recombinant protein-based biopolymers with controlled properties, and produce them via fermentative processes. We develop biopolymeric materials with adjustable mechanical properties, programmed functionalities, or the ability to adapt or respond to the environment. We use a range of chemical and physical characterisation techniques to develop a rational understanding of their self-assembly, mechanical properties, structures, and dynamic features.

Living and composite biopolymeric materials

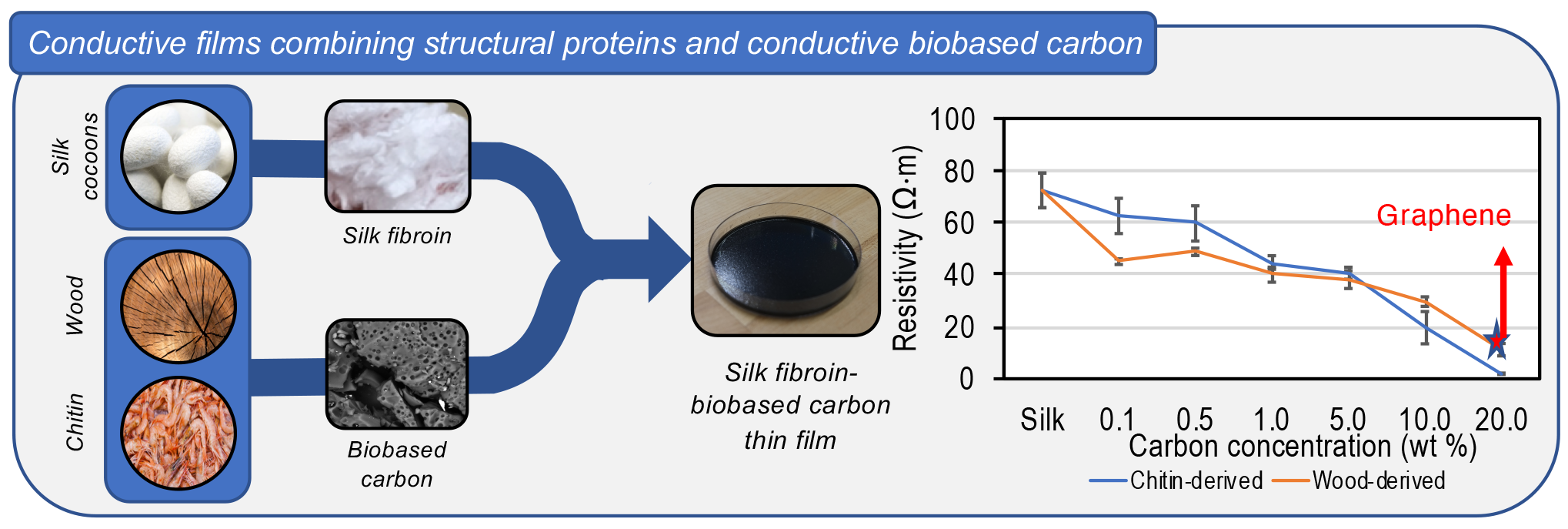

Natural and synthetic biopolymeric materials can be combined with additives to enhance their functionalities. We are interested in two types of additives: (1) microorganisms capable of secreting functional molecules to create living materials; and (2) biobased carbons or biominerals to create composite materials.

On the one hand, microorganisms with tweaked biological functions can be developed and embedded in biopolymers to form living materials. These materials hybridise animate and inanimate elements, and display spatiotemporally dynamic architectures that grow and adapt to environmental signals. On the other hand, biobased carbons or biominerals provide us with an extra layer of control of the mechanical, structural, electrical... properties of biopolymers.

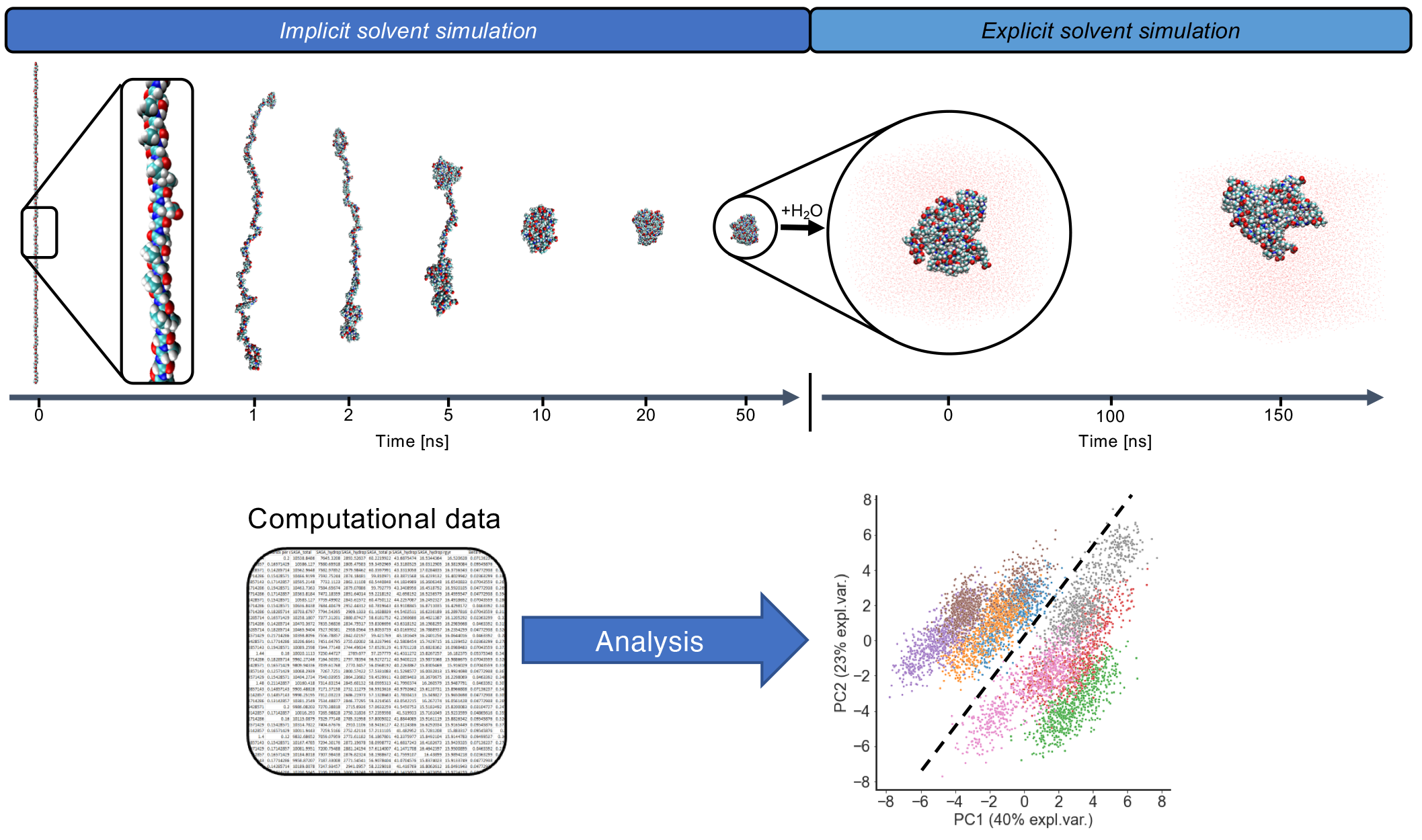

Computational studies on structure-property relationships

We use computational models to understand phenomena that exist at a hierarchy of time- and length-scales in biopolymeric and composite materials, mainly through fully-atomistic and coarse-grained molecular dynamics (MD) simulations. These simulations allow us to study hierarchical chemical details of biopolymers down to the nanoscale (e.g., chain topologies, interfacial interactions) that are vital to develop a fundamental understanding of the behaviour on a meso- to macroscopic scale of materials developed from them. Moreover, we seek to embed modelling into the early stages of material design, in order to improve the time efficiency to develop new materials while reducing the cost for experimentation.